Reducer Motor

Item: Motor

Details:

Cycloid reducer

First, cycloid reducer, is the structure of a novel application of the reduction mechanism transmission principle, the use of swing needle teeth meshing, advanced design. The reducer can be widely used in various mechanical reduction gear mechanism.

Second, the structural principle.

Full cycloid gearing can be divided into three parts: input part, slow down part and output part.

The input shaft with a dislocation of 180 ° double eccentric, the eccentric sleeve is equipped with two roller bearings, which form the H organizations, the center hole is the two cycloid eccentric sleeve bearing raceway jib and meshed by the cycloid pin gear and a group of ring gear needle arrangement, a combination of small teeth difference in the meshing gear box, (to reduce friction in a small gear ratio, the needle with the needle teeth gear sets ).

When the input shaft with eccentric rotate a round, due to the characteristics of the tooth profile cycloid needle teeth and therefore limiting the subject, cycloid motion have become a planar motion of both rotation and revolution,when the input shaft corotates a round , the eccentric also rotates a round, one tooth difference cycloid wheel rotation resulting deceleration in the opposite direction, then with W output mechanism, the low-speed rotation of the cycloid movement through the pin, transmitted to the output shaft, thereby obtaining a lower output speed.

Third,characteristics.

1 .Big transmission ratio: The transmission ratio of first reduction is 1/6 ~ 1/87;and it raises to 1/99 ~ 1/7569 when double reduction; you can use more combinations according to need.

2. Efficient transmission: Due to the engagement with a rolling engagement, the average efficiency is up to 90%.

3. Compact construction and small size: The machine not only uses the principle of planetary transmission that input shaft and the output shaft are on the same axis, but also directly associated with the motor which is unique.

4. Few fault, long life: The main transmission meshing assembly unit of this machine uses ball bearing steels,which is good mechanical properties, wear resistance and strong; couple with rolling friction, it has low friction losses.

5. Smooth and reliable operation: The machine is more meshing transmission process, operate smoothly with low noise.

6. Reasonable structure design: Simple installation and removal, easy maintenance.

7. The machine has strong overload capacity, impact resistance, low moment of inertia for frequent starting and reversing occasions.

8. The machine uses a special grease, suits temperature -50 ° to 80 °

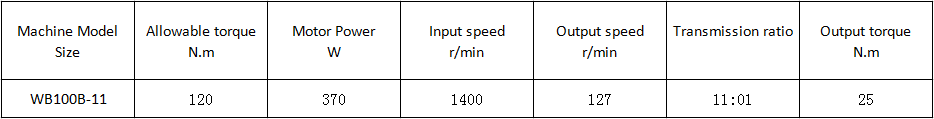

Fourth, the performance index:

Fifth, the use and installation

1. The gear system allows the use of continuous work and frequent starting occasions, allowing positive and reverse direction; the input and output shafts rotate in opposite directions.Fifth, use and installation

2. The gear can be installed at any angle to use.

3. The output shaft can not withstand large radial and axial forces, when there are large radial and axial forces of occasions, it should be taken appropriate measures to unloading.

4. Direct Connect motor reducer should be strictly in accordance with the insulation of the motor within the scope of protection to use, and should be well grounded, ambient temperature from -50 ° to 80 °.

5. In the gearhead output shaft pulley mounted connector, do not allow the direct use of hammer, screw shaft should use a screw and plate push, to avoid damage to the motor and gear reducer.

6. When donging reducer flange stopping positioning installation, shaft hole and coaxial connectors and verticality spigot should be within the allowable range.

Sixth Notes

The reducer machine motor rotation system fitted with a hand fan site, with a dedicated random swing, swing required to use manual operation, you must first shut down power off to ensure safety!